Lokacin da samfurin ya tafi matakin yin ƙira, lokacin jagora yana da matukar mahimmanci don tabbatar da cewa samfuran zasu iya ƙaddamar da kasuwa akan lokaci.Don haka, idan lokacin jagoran kayan aiki zai iya zama ɗan gajeren lokaci, zai taimaka da yawa ga abokan ciniki na ƙarshe don kawo sabbin samfuran su zuwa kasuwa.Sa'an nan, yadda za a yi filastik allura molds tare da guntu gubar lokaci?A ƙasa ra'ayinmu ne don tunani.

1. Masu samar da kayayyaki suna buƙatar neman lokacin buƙatun abokan ciniki don samfuran samfura da ƙira da farko don su iya kimanta layin lokaci mai wahala don wannan aikin.(Idan ba za su iya yin hakan ba, dole ne su kasance masu gaskiya ga abokan ciniki.)

2. Rage lokacin ƙira.Lokacin da sashi ya tafi matakin kayan aiki, yawanci akwai wurare da yawa da ke buƙatar canzawa don sanya shi dacewa da kayan aiki, kamar canza kusurwar daftarin aiki, kaurin bango da yanke ƙasa da sauransu.A wannan yanayin, sadarwa tsakanin injiniyoyin abokan ciniki da masu samar da kayan kwalliya suna da tasiri sosai.Lokacin rana yana yin DFMs ga abokan ciniki a gaba don nuna wuraren da muke tunanin buƙatar canzawa da aika wa abokan ciniki cikin sauri cikin kwanaki 1 ~ 3 dangane da adadin sassa da rikitarwa.Tallace-tallace da injiniyoyi koyaushe suna ba da tunatarwa akan lokaci kuma suna bin diddigin ra'ayoyin abokan ciniki don guje wa yuwuwar ɓata lokaci.Bayan DFM yayi kyau, za mu fara yin ƙirar 2D, koda kuwa kuɗin ajiya bai zo mana ba.Domin adana lokaci, koyaushe muna yin ƙira a gaba.Yawanci, 2D mold zane bukatar 1 ~ 3 aiki kwanaki da 3D mold zane bukatar 2 ~ 4 aiki kwanaki.Masu zanen mu suna aiki sosai kuma yana tabbatar da ɗan gajeren lokacin ƙirar mu.

3. A lokacin zane-zane, sauƙi & cikakkiyar fahimtar juna da kuma sadarwar lokaci yana da mahimmanci, yana iya adana lokaci don imel ɗin da ba dole ba ko kiran waya.Ƙungiya mai ƙira na lokacin rana na iya yin magana da rubuta Turanci sosai, injiniyoyi za su iya ba da amsa imel ɗin Ingilishi kai tsaye.Kuma lokacin da ake buƙatar samun kiran taro, ƙungiyarmu za ta iya yin hakan kowane lokaci.

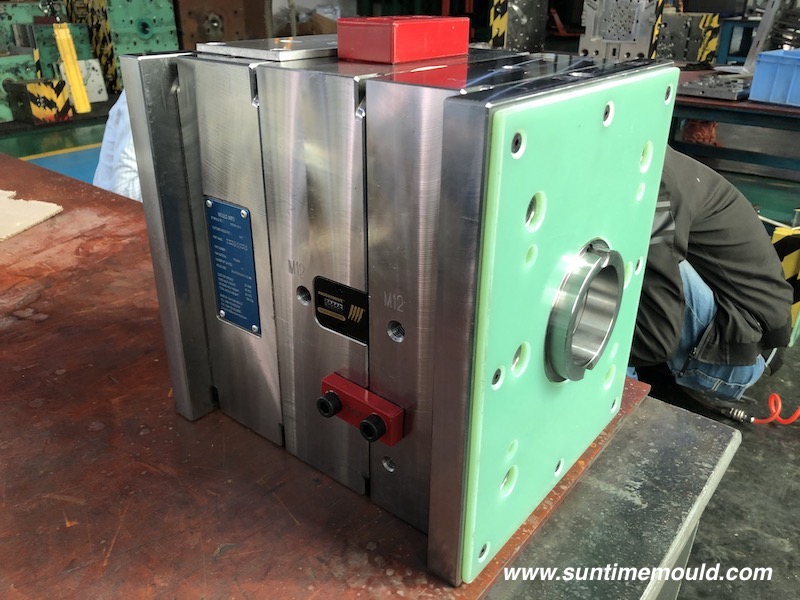

4. Sa'an nan, ya zo ga mold masana'antu mataki.A ka'ida, ba za a iya yanke lokacin masana'antu ba kamar yadda duk mun san cewa inganci mai kyau yana buƙatar isasshen lokaci.Duk da haka, ko da yaushe akwai gaggawa yanayi wani lokacin.Lokacin da abokan ciniki ke buƙatar ɗan gajeren lokaci, ƙungiyar ƙira ta Suntime na iya yin gwajin T1 mold kwanaki 1 ~ 2 gaba ta hanyar tsara dare aiki kyauta.Amma, shawararmu ba ita ce turawa da yawa don masana'antu ba.

5. Yanzu, shine abu mafi mahimmanci don taƙaita jimlar lokacin jagora - adadin lokuta na gwaji.An ƙayyadadden lokacin yin ƙirƙira, amma ba a ƙayyadadden gwajin ƙira kamar yadda gyare-gyare da gyare-gyare ke faruwa sau da yawa.Yawan gwaje-gwajen mold shine babban yuwuwar ɓata lokaci.Bayan T1, masu kaya da farko suna buƙatar duba matsalolin kuma idan tsarin ƙirar da kayan haɓaka suna buƙatar haɓaka;duba sigar gyare-gyare don ganin ko akwai hanya mafi kyau don yin gyare-gyaren allura.Kuma idan tsarin ƙira ba zai iya taimakawa ba, injiniyoyi suna buƙatar gano ko akwai sauran batutuwa a cikin tsarin ɓangaren da yadda za a yi canjin bisa ga rashin canza tsarin haɗuwa.Bayan samun ƙarshe na ƙarshe, injiniyoyi suna buƙatar yin rahoton gwaji na mold tare da hotuna don nuna batutuwan da mafitarmu don amincewar abokin ciniki.A lokaci guda, ana buƙatar samar da bidiyon hanyar ƙirar ƙira, sigar ƙira da rahoton duba samfuran ga abokan ciniki don tattaunawa.Bayan samun amincewar abokan ciniki na gyara & gyare-gyare, muna buƙatar shirya aikin a lokaci ɗaya kuma muyi mafi kyau don gyara duk batutuwa a gwaji na gaba.A al'ada, don ƙananan batutuwa, T2 na iya faruwa bayan mako 1, kuma don matsaloli masu rikitarwa, watakila yana buƙatar makonni 2.Sarrafa jimlar adadin hanyoyin cikin sau 3 hanya ce mai kyau don adana lokaci & farashi.

Suntime mold suna da shekaru masu yawa na gwaninta aiki tare da abokan ciniki na duniya, gamsuwar su shine babban kwarin gwiwarmu mu ce za mu iya aiki tare da ku sosai.

Lokacin aikawa: Nuwamba-09-2021