Aluminum mutu simintin gyare-gyaren tsari ne wanda ake tilastawa narkakkar aluminum gami a cikin wani karfe mutu ko mold karkashin matsin lamba.Yawancin lokaci ana aiki da shi don samarwa da yawa kuma yana iya samar da sassa tare da cikakkun bayanai masu rikitarwa da kuma abubuwan haɗin gwiwa tare da matsatsin haƙuri a ɗan ƙaramin farashi.Sassan da aka samar daga simintin mutuwa na aluminum suna da kyawawan kaddarorin inji kuma suna da juriya ga lalata, zafi, da lalacewa.

• Aluminum die simintin yana ba da fa'idodi da yawa, wasu daga cikinsu sun haɗa da:

• Nau'i masu nauyi da ƙarfi waɗanda suka fi sauran nau'ikan karafa masu tsada

• Ingantaccen aiki saboda guntun lokacin gubar da rage sharar gida

• Ƙara 'yancin ƙira saboda rashin lafiyarsa, yana ba da damar ƙirƙirar siffofi masu rikitarwa da sauri da sauƙi

• Babban juriya ga lalata, zafi, da lalacewa idan aka kwatanta da sauran karafa

• Ƙarfafawa don samar da taro, tare da mafi yawan allunan aluminium masu iya tsayayya da matsa lamba da yanayin zafi

Aluminum mutu simintin gyare-gyare hanya ce mai ban sha'awa ta masana'anta da ake amfani da ita don samar da sassa daban-daban na masana'antu daban-daban.Daga abubuwan da ke keɓancewa na kera motoci zuwa ƙwararrun likitanci da ƙari, ana iya amfani da simintin kashe aluminum don ƙirƙirar kusan komai, kamar:

• Masana'antar kera motoci:Daban-daban sassa ciki har da datsa ciki, watsa casings, injin tubalan da hawa hawa, radiators, da caji tsarin.

• Masana'antar sararin samaniya:Abubuwan hadaddun abubuwa kamar famfo, na'urori masu auna firikwensin, masu kunna wuta, hasumiya ta rediyo da eriya.

• Masana'antar likitanci:Abubuwan musamman na musamman kamar su bawul ɗin zuciya da za a iya dasa su, kayan aikin tiyata, orthotics da prosthetics.

• Kayan aikin gida:Hinges da latches don firiji da injin wanki da sauran ƙananan abubuwan da ke buƙatar aiki mai rikitarwa.

• da sauransu,.

Zaɓin madaidaicin alloy na aluminium don aikin simintin mutuwa yana da mahimmanci don tabbatar da cewa ƙãre samfurin ku ya dace da duk ƙayyadaddun ƙayyadaddun ku.Anan akwai wasu shawarwari akan zabar abin da ya dace:

• Yi la'akari da ƙarfi da buƙatun dorewa na ɓangaren ku.Alloys daban-daban suna ba da matakan ƙarfi daban-daban da juriya, don haka yana da mahimmanci a zaɓi abin da zai dace da bukatun aikace-aikacen ku.

• Kimanta matakin juriya da ake buƙata.Aluminum gami za a iya bi da su da anodized don samar da ƙarin kariya daga lalata, don haka tabbatar da la'akari da yanayin da sassan ku zasu buƙaci jurewa.

• Yi la'akari da farashin samarwa da lokutan bayarwa.Dangane da rikitaccen ɓangaren, alloys daban-daban na iya buƙatar hanyoyin samarwa daban-daban ko saka hannun jari na kayan aiki, don haka yana da mahimmanci a auna waɗannan abubuwan yayin zaɓin gami don aikin ku.

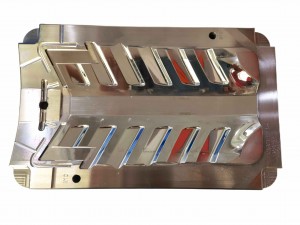

Bukatun kayan aiki da machining don aluminium mutu simintin sun bambanta dangane da gami da ake amfani da su, da sarƙaƙƙiyar ɓangaren, da sauran abubuwa.Gabaɗaya, yana da mahimmanci a yi la'akari da waɗannan abubuwan yayin zabar nau'in kayan aiki:

• Zaɓin kayan aikin kayan aiki ya kamata ya dogara ne akan haɗin da ake amfani da shi da yanayin zafi da ake bukata don samar da sakamako mai kyau.Mu yawanci muna amfani da H13, SKD61, 8407, 8418, 8433 da W360 don kayan aikin simintin mutuƙar.

• Dole ne a kula don tabbatar da cewa akwai isasshiyar kusurwa ta yadda abubuwan da ke cikin su za su iya motsawa cikin sauƙi daga mutuwa lokacin da aka fitar da su.Ya kamata a yi cikakken bincike na DFM kafin ƙirar ƙira.

• Ana iya buƙatar mashin ɗin na biyu bayan simintin gyare-gyare don cimma wasu siffofi ko cikakkun bayanai, ya haɗa da injin CNC, hakowa, tapping da sauransu.

Zaɓuɓɓukan Kammala saman saman kamar fashewar yashi ko gogewar girgiza, anodizing, plating ko zane na iya zama larura dangane da bukatunku.

CNC Machining for Die Casted Parts

Shirya matsala na gama gari a cikin simintin gyare-gyare na aluminum na iya zama tsari mai cin lokaci da tsada, amma yana da mahimmanci don tabbatar da ingancin kayan aikin ku.Anan akwai wasu nasihu akan magance matsalolin gama gari tare da simintin gyare-gyare na aluminum:

• Rashin ƙarfi:Bincika ɓangaren ku don kowane ramuka ko wasu wuraren da zai iya haifar da porosity.Idan kun sami wani, tabbatar da yin bitar zafin jiki, matsa lamba na allura da sauran abubuwan da wataƙila sun shafi cikon yanki.

• Karya:Idan kun sami murdiya a sassa bayan an cire su daga mutuwa, duba don ganin ko ƙirar ƙira ko lokutan sanyaya na iya haifar da wannan batu.Kuna iya buƙatar daidaita waɗannan saitunan don ayyukan samarwa na gaba don rage duk wani murdiya.

Lalacewar saman:Idan kun haɗu da kowane lahani na saman kamar alamar splay ko fins, duba ko akwai rashin daidaituwa tsakanin saurin allura da narkar da kwararar ruwa, saboda wannan na iya haifar da waɗannan batutuwan.Hakanan yana iya zama larura don daidaita sigogin simintin gyare-gyare kamar zafin jiki da ƙimar sanyaya don rage ƙarancin ƙasa.

Lokacin da aka fara sabon aiki, ana buƙatar sassan samfuri cikin sauri don nau'ikan gwaji.Akwai hanyoyi da yawa don yin samfura ciki har da injina na CNC, Vacuum simintin gyare-gyare, bugu na 3D da kayan aikin samfur na gaggawa.

• CNC machining iya yin karfe da filastik sassa tare da kowane yawa.

• Vacuum Casting shine na sassan filastik na raka'a 5-100 ta amfani da gyare-gyaren silicon

• Buga 3D shine don buga sassan ABS, PA ko Karfe.Don filastik, sassan 3D da aka buga ba za su iya jure yanayin zafi ba.

• Kayan aikin samfur na sauri shine mold mai laushi wanda aka yi ta ƙarfe mai laushi kamar S50C ko Aluminum.Wannan bayani zai iya samar da ƙarin sassa fiye da Vacuum simintin.Lokacin jagora ya fi guntu kayan aikin samarwa kuma farashin ya yi ƙasa sosai.

Abubuwan da muka yi amfani da su: Filastik kamar PC, PMMA, POM, PP da sauransu,.Karfe kamar karfe, aluminum, tagulla, jan karfe da sauransu.

Yadda ake yin sassan silicon

Don ƙirƙirar ɓangaren silicone, kuna buƙatar amfani da tsari na gyare-gyaren allura.Wannan ya hada da narka robobi a cikin injin allura da allura a cikin wani rufaffiyar rami, inda zai yi sanyi ya taurare ya dauki siffar da ake so.

Sauran hanyoyin da za ku iya amfani da su sun haɗa da gyare-gyaren latsa, simintin gyare-gyare, ko bugu na 3D.Kowace hanya tana ba da fa'idodi na musamman da rashin amfani dangane da nau'in ɓangaren da kuke ƙoƙarin ƙirƙirar.

Tare da duk hanyoyin, samun madaidaicin zafin jiki da matsa lamba shine mabuɗin don samun ingantattun ma'auni da ƙayyadaddun kayan ƙaya.

Na'urorin silicon sassa

Akwai masana'antu da yawa da za su iya amfani da sassa masu laushi na silicon kamar Automotive, Medical, Electronic, houseware, kitchenware, da sauran su.Ga sassa, yawanci zaka iya samun waɗannan kamar Gasket, Seals, O-rings, Fitar iska, Hoses, Abubuwan Haske, Cakulan wayar hannu, murfin allo, Wayoyi da igiyoyi da na'urorin lafiya da yawa.

Sassan hatimin ƙarfe su ne abubuwan ƙarfe waɗanda aka ƙirƙira ta hanyar aiwatar da tambarin ƙarfe, dabarar masana'anta wacce ta ƙunshi naushi, yanke, ko ƙirƙirar zanen ƙarfe zuwa sifofin da ake so.

Ana amfani da tambarin ƙarfe don ƙirƙirar sassa don masana'antu iri-iri da suka haɗa da masana'antar kera motoci da na sararin samaniya.

Hakanan za'a iya amfani dashi don ƙirƙirar sifofi na al'ada da rikitarwa.Fa'idodin yin amfani da tambarin ƙarfe sun haɗa da ingancin farashi, ƙira da sassauci.

SPM ya taimaka wa abokan ciniki a yawancin kayan tambarin ƙarfe don aikin maɓalli na su, ingantaccen aikin injiniyan mu na iya adana kuɗi da lokaci mai yawa.

Jigs da kayan aiki kayan aiki ne da ake amfani da su don taimakawa wajen kera sassa da sassa daban-daban.

Jig kayan aiki ne na musamman wanda ke taimakawa jagora, riko, ko sanya kayan aiki a wurin yayin ayyukan injina daban-daban, kamar hakowa, niƙa, da tsarawa.

Kayan aiki sune na'urori waɗanda ke makale da na'ura ko benci na aiki kuma suna taimakawa ganowa da amintar sassan yayin da ake aiki da su.

Ana iya tsara su na al'ada don ɗaukar ayyuka daban-daban don tabbatar da daidaito da inganci.Dukansu jigs da kayan aiki za a iya yin su da karfe irin su karfe ko aluminum kuma suna da mahimmanci don samar da daidaitattun abubuwa tare da ƙananan ƙoƙari.

SPM yana yin jigs da kayan aiki don samar da namu allura gyare-gyaren kuma samar da sabis na yin su ga abokan ciniki.

Idan kuna da buƙatar wannan, tuntuɓi kowane lokaci.