Abubuwan da kuke son sani game da ƙwayar allura

Kyakkyawan ƙirar ƙira shine farawa mai mahimmanci.Tare da zanen ɓangaren ku (2d/3d), masu zanen mu da injiniyoyi za su sami taro don tattauna tsarin ɓangaren, matsaloli, buƙatun abokin ciniki da samun ra'ayi na ƙirar ƙira don shi.

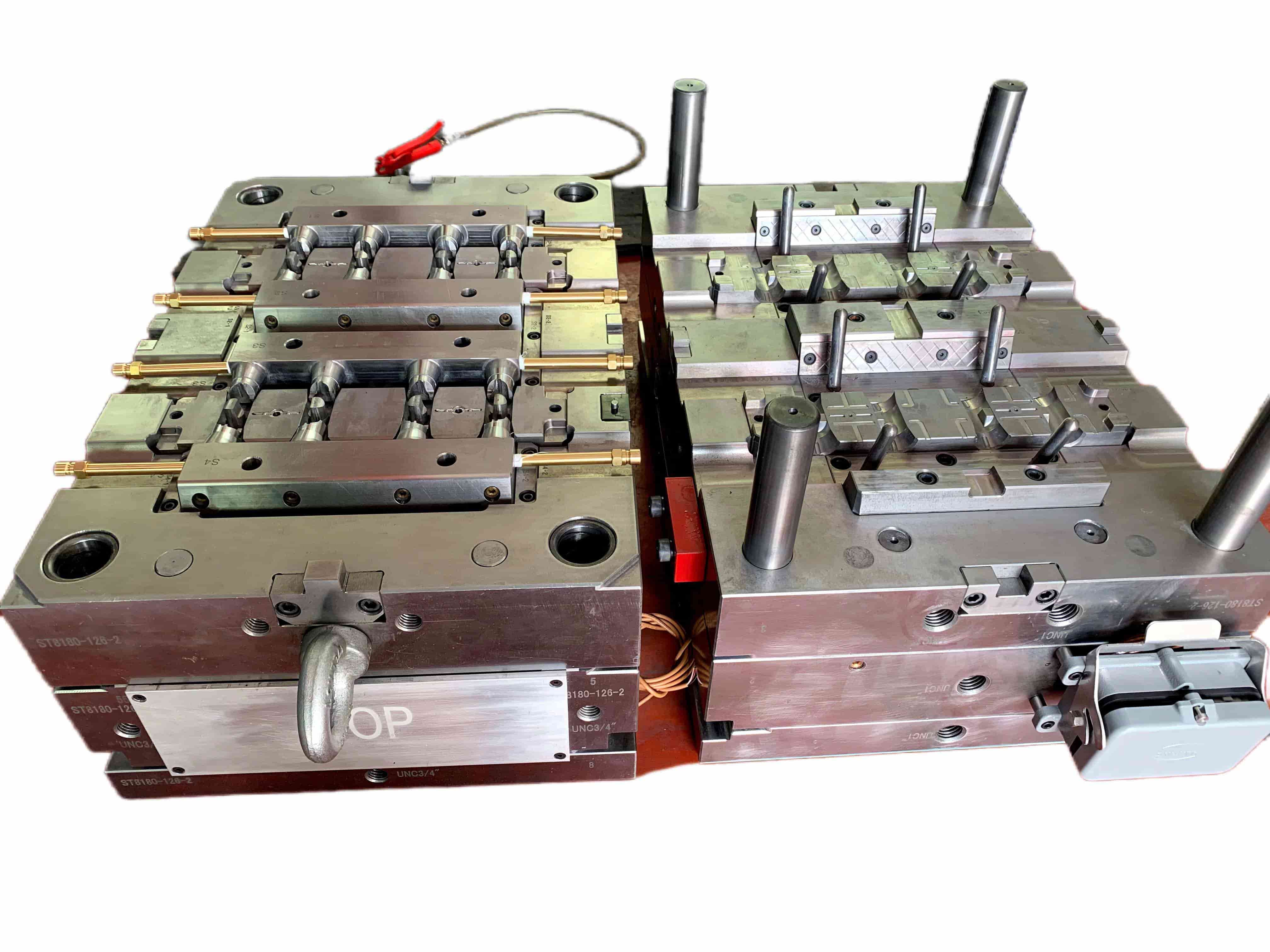

1. DFM: nuna mold layout ra'ayi, sanyaya, allura tsarin, ejection tsarin, bango kauri, daftarin kwana, engraving, surface karewa, zane gazawar yanayin da sakamakon bincike da sauran mold saki al'amurran da suka shafi.

2. Mold kwarara ( tayin cikin kwanaki 1 ~ 3)

3. Mold 2D layout zane ( tayin cikin kwanaki 2 ~ 4)

4. Mold 3D zane (software: UG, tayin a cikin 2 ~ 5days)

Mene ne m m?Dole ne ya kasance yana da inganci mai kyau don saduwa da buƙatun samar da kwanciyar hankali da kwanciyar hankali, kuma babu buƙatar ciyar da lokaci mai yawa & farashi don kulawa da gyarawa.

Suntime yana da masu zanen kaya 6 a cikin duka tare da ƙwarewar fiye da shekaru 5-10, koyaushe suna ba da kulawa ta musamman akan ƙayyadaddun abokan ciniki da cikakkun bayanai ta hanyar tunani game da mafita mai ceton farashi dangane da kwanciyar hankali da inganci.Kwarewarsu ta shekaru don fitar da gyaggyarawa tana ba su babban ilimi don ƙa'idodin ƙirar ƙirar duniya da buƙatun inganci.

Bayanin ƙirar ƙira don murfin hasken mota

Mai yin allurar filastik na iya taimaka wa abokan ciniki ta hanyoyi daban-daban.Za mu iya ƙirƙirar sassa na filastik na al'ada waɗanda suka dace da ƙayyadaddun ƙayyadaddun su da buƙatun su.Za mu iya bayar da ƙira da aikin injiniya don tabbatar da cewa samfurin ƙarshe ya dace da ainihin bukatun abokin ciniki.Kuma muna ba da sabis bayan sabis kamar kulawa da gyare-gyare don gyare-gyaren allura na filastik don kiyaye su da kyau a cikin masana'antar mu ko a cikin kamfanin abokan ciniki.

A matsayin kayan aikin allura, za mu iya yi muku kamar haka:

1. Tallafin tallace-tallace na farko ciki har da amma ba'a iyakancewa ba a cikin bayar da zance mai sauri, mai ba da shawara na zaɓuɓɓukan kayan aiki, kayan aiki na DFM bincike da sauransu.

2. Tsarin ƙira daga DFM, ƙirar ƙirar 2D, ƙirar 2D da ƙirar 3D.(a cikin kwanaki 2-4 na aiki)

3. Custom mold masana'antu for Plastics & Aluminum.

4. Sabis na injiniya don bin aikin da sauran ayyukan da suka danganci waje

5. Mold gwaje-gwaje da kuma low girma allura gyare-gyaren samar da mold shipping

6. Mold gyara / gyara da sauri

7. jigilar jigilar kayayyaki ta iska, ruwa ko jirgin kasa.

Me muke yi don gudanar da aikin ku (gudanar da aiki)?

Mataki na 1:Tare da zanen sassan abokan ciniki (2D&3D) da ƙayyadaddun bayanai, muna gudanar da tarurrukan farawa tare da masu zanen kaya, injiniyoyi da manajan aiki tare don koyan cikakkun bayanai da yin memo don ayyukan.

Mataki na 2:Bayan amincewar abokan ciniki don DFM, sun fara shimfidar 2D & 3D mold zane & Mold kwarara bincike a cikin ɗan gajeren lokaci.

Mataki na 3:A yayin duk aikin, za a ba da rahoton mako-mako kowane Litinin don tabbatar da cewa abokan ciniki suna da komai a ƙarƙashin iko.

Mataki na 4:Don gwaje-gwajen mold, muna aika rahoton gwaji tare da hotuna masu ƙura, hotuna samfurori, hoton ɗan gajeren hoto, hoto mai nauyi, al'amurran gyare-gyare da mafita.

A halin yanzu, Za a samar da Bidiyo Molding, rahoton dubawa da sigar gyare-gyare da sauri da sauri bayan.

Mataki na 5:Tare da amincewar abokan ciniki don aika samfurori, muna aika sassa ta bayyana a ƙarƙashin asusun Suntime.

Mataki na 6:Za a fara gyaran gyare-gyare ko gyare-gyare a lokaci ɗaya bayan sadarwa tare da abokan ciniki.

Mataki na 7:Ana iya jigilar mold tare da amincewar abokan ciniki.Fiye da 50% molds ana buƙatar aikawa bayan T1.

Mataki na 8:Kunshin jigilar kaya gami da: sandar ƙwaƙwalwar ajiya tare da ƙirar ƙirar 2D&3D ta ƙarshe, BOM, takaddun shaida, hotuna da wasu kayan gyara.

Mataki na 9:Tsaftace kyawon tsafta da dubawa sau biyu tare da lissafin duba QC kafin shiryawa.

Mataki na 10:Vacuum packing don sufuri.

Mataki na 11:Takardu da tallafin tallace-tallace don ba da izini na al'ada.

Za a ba da ƙididdiga a cikin sa'o'i 24 daga SPM!

Da fatan za a aiko mana da zane-zanen sashi na 2D/3D don zance cikin sauri.

Idan babu zane-zane, bayyanannun hotuna da ke nuna tsari da girma, ko, samfurori zuwa masana'antar mu kai tsaye.

Tsarin fayil: Dwg, Dxf, Edrw, Mataki, Igs, X_T

Tsarin matakai na masana'anta don ƙirar allura

Za a iya rushe tsarin yin gyare-gyare na filastik zuwa matakai masu zuwa:

Zane:DFM bincike don moldability.Ƙirƙiri zane-zane na 2D&3D.

Injiniya:Yanke karfe kuma amfani da injuna kamar CNC, EDM, lathe da sauransu don yin siffa bisa zane.

Ƙarfafawa:Zafi ya yi maganin karfe don sa su kai ga taurin kuma mafi dorewa.

saman:gogewa da laushi don saduwa da buƙatun kayan kwalliya.

Taro & Daidaitawa:Haɗa duk abubuwan da ke cikin ƙirar ƙarshe kuma yi dacewa.

Gwajin Mold:Gwada cewa komai yana aiki da kyau bayan taro.

Dubawa:Tare da gyare-gyaren sassa, yin bincike na ƙira da samfurori ta hanyar CMM, majigi, da dai sauransu,.

Gyarawa/gyara:Dangane da samfuran, yi gyare-gyare ko gyare-gyare waɗanda abokan ciniki ke buƙata.

Ship molds bayan abokan ciniki' yarda.

Yadda za a ajiye farashi don yin ƙirar allura?

Yadda za a ajiye farashi don yin mold?Da fari dai, ya kamata ka san manufar mold.Me za ku yi amfani da shi?Menene girman abin da kuke son ƙirƙirar?Menene adadin shekara?Kogo nawa kuke bukata?Kuma yaya daidaito kuke so?Duk waɗannan abubuwan zasu shafi farashin ƙirar.

• Sauƙaƙe ƙira gwargwadon yiwuwa.Mafi hadaddun ƙirar ɓangaren shine, mafi tsadar ƙirar zata kasance.Idan za ku iya sauƙaƙe zane, za ku adana kuɗi.

• Yi amfani da daidaitattun kayan aiki.Za'a iya rage farashin ƙirar allura ta amfani da daidaitattun kayan maimakon kayan ƙaya.

• Yi amfani da lissafi mai sauƙi.Mafi sauƙi na lissafi, ƙarancin tsadar ƙirar za ta kasance.

• Rage yawan layin rabuwa.Layukan rabuwa sune inda rabi biyu na mold suka hadu.Yawancin layin rabuwa akwai, mafi tsadar ƙirar zai kasance.

• Rage adadin muryoyi da abubuwan da aka saka.Madogarai da abubuwan da ake sakawa su ne guda waɗanda ake amfani da su don ƙirƙirar cavities a cikin ƙirar.Da yawan muryoyi da abubuwan da ake sakawa a can, mafi tsadar ƙirar za ta kasance.

• Yi amfani da tsarin masana'antu na al'ada.Za a iya rage farashin ƙirar allura ta hanyar yin amfani da tsarin ƙirar al'ada maimakon tsarin al'ada.

• Yi amfani da ƙirar ƙofa mai sauƙi.Ƙofar ita ce wurin da kayan ke shiga cikin rami a lokacin masana'anta na allura.Ƙofar ƙofa mai sauƙi zai rage duka ɓarna na kayan abu da lokacin sake zagayowar, wanda zai adana kuɗi.

Idan kana da wani bangare a hannunka da ke buƙatar yin ƙirar allura, amma ba ka da tabbacin yadda za a adana farashi kamar yadda zai yiwu, tuntube mu, za mu samar da bincike na DFM kyauta kuma mu sanar da kai ra'ayoyinmu.

FAQ

Custom roba allura mold masana'anta

Aluminum mutu simintin gyaran kafa

Na al'ada roba allura mold

Multi-rago allura mold

Tsarin iyali

Hot runner tsarin mold

MUD m

Sama da mold

2k m

Sirin bango mold

Saurin samfurin ƙira

Gudun Motsi: Ƙirar Ƙirar Ƙira

3D Modeling: Unigraphics, Pro/Injiniya, Solidworks (fayil: mataki, Igs, XT, prt, sldprt.)

Zane na 2D: Auto-CAD, E-zane (fayil: dwg, dxf, edrw)

Karfe Brand: GROEDITZ/ LKM/ ASSAB/ DAIDO/ FINKL...

Mold Base: LKM, DME, HASCO, STEIHL ....

StandardComponents: DME, HASCO, LKM, Meusburger….

Hot Gunner: Mold master, Mastertip, Masterflow, Husky, Hasco, DME, Yudo, Incoe, Syventive, Mold master…

Goge/Texture: SPI,VDI, Mold-Tech, YS.... Gyaran

PEEK, PPSU, ABS, PC, PC + ABS, PMMA, PP, HIPS, PE (HDPE, MDPE, LDPE).PA12, PA66, PA66 + GF, TPE, TPR, TPU, PPSU, LCP, POM, PVDF, PET, PBT, da dai sauransu.

A380, AL6061, AL5052, da dai sauransu.

DFM/Mold kwarara: 1 ~ 3 kwanakin aiki

2D zane: 2 ~ 4 kwanakin aiki

3D zane: 3 ~ 5 kwanakin aiki

Magana a cikin sa'o'i 24!

Kuna iya tuntuɓar mu ta imel, kiran waya,taron bidiyo,ko buƙatar ziyara

Injiniya suna tuntuɓar kai tsaye cikin Ingilishi

Lokacin jagorar masana'anta (daga amincewar ƙira zuwa T1) shine makonni 3 ~ 8 ya dogara da rikitarwa da tsari.

Amma don ayyukan al'ada, yana da makonni 4 ~ 5.

Ee, muna ISO9001: 2015 takaddun shaida

Ee, muna da injunan gyare-gyaren allura guda 7.

Babban abokan cinikinmu suna cikin Arewacin Amurka (Amurka, Kanada), Turai (Jamus, UK, Norway, Denmark, Portugal da sauransu) da Ostiraliya