| Kayan aiki da Nau'in | Ingantattun abubuwan lantarki da aka yi ta hanyar allurar filastik da yawa, | |||||

| Sunan sashi | Mai haɗa wayar hannu | |||||

| Guduro | Foda karafa kayan | |||||

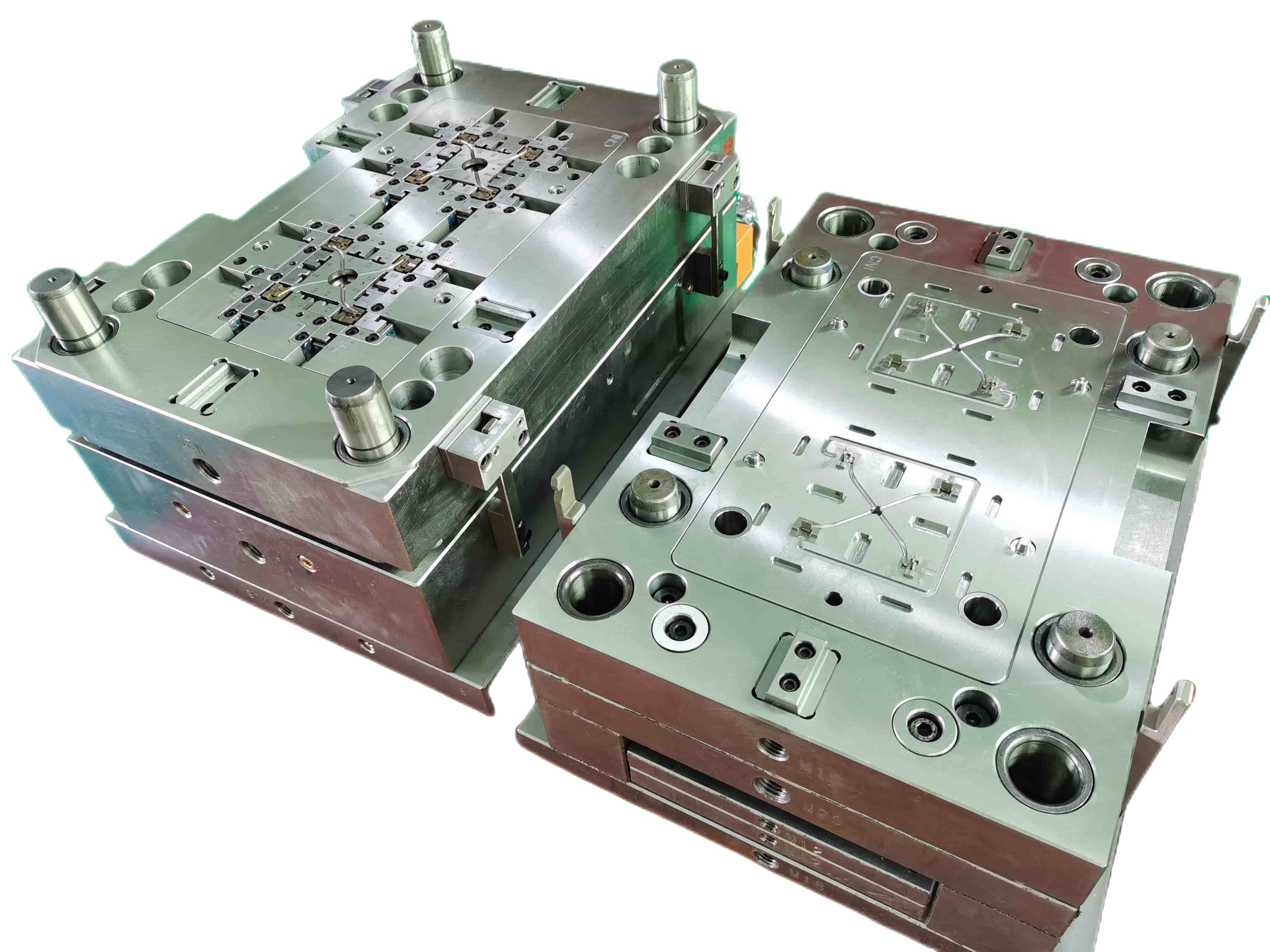

| No. na rami | 1*8 | |||||

| Tushen Motsi | S50C | |||||

| Karfe na rami&Core | S136 HRC 52-54 | |||||

| Nauyin kayan aiki | 450KG | |||||

| Girman kayan aiki | 450X350X370mm | |||||

| Danna Ton | 90T | |||||

| Mold rayuwa | 1000000 harbi | |||||

| Tsarin allura | Hot mai gudu, 2pcs Mold-master hot tips | |||||

| Tsarin sanyaya | Cooling da man fetur, mold zafin jiki 120 digiri | |||||

| Tsarin fitarwa | Korar matakai biyu | |||||

| Maki na musamman | Foda karfe kayan aiki, daidai allura mold, zafi mai gudu, 8 cavity mold, gajeren lokacin sake zagayowar | |||||

| Wahala | High daidaici haƙuri, high zafin jiki mold, short mold yin gubar lokaci da kuma gajeren gyare-gyaren sake zagayowar lokaci.Kayan shine kayan ƙarfe na foda yana da ɗan gajeren lokacin sanyaya da babban buƙatar injin allura. | |||||

| Lokacin jagora | makonni 4 | |||||

| Kunshin | Mold zauna a China don samar da gyare-gyaren filastik | |||||

| Shiryawa abubuwa | Takaddun shaida na karfe, ƙirar kayan aikin 2D na ƙarshe & 3D, takaddar gudu mai zafi, kayan gyara da na'urorin lantarki… | |||||

| Ragewa | 1.005 | |||||

| Ƙarshen saman | SPI B-1 | |||||

| Lokacin sake zagayowar allura | 9 seconds | |||||

| Na biyu jiyya na samfurori bayan gyare-gyare | Maganin zafi don samfuran gyare-gyare | |||||

| Fitarwa zuwa | Mold zauna a China don samar da gyare-gyaren filastik | |||||

Matsalolin

High daidaici haƙuri, high zafin jiki mold, short mold yin gubar lokaci da kuma gajeren gyare-gyaren sake zagayowar lokaci.

Kayan shine kayan ƙarfe na foda yana da ɗan gajeren lokacin sanyaya da babban buƙatar injin allura.

Mene ne foda metallurgy?

Ƙarfe na foda wani tsari ne na masana'antu wanda ke amfani da matsa lamba da ɓarke barbashin ƙarfe don ƙirƙirar sassa da sassa daban-daban.Tsarin ya haɗa da haɗa nau'ikan karafa irin su ƙarfe, aluminum, tagulla, bakin karfe da cobalt tare da man shafawa da abubuwan ɗaure kafin a jefa su cikin matsanancin matsin lamba.Sakamakon cakuda yana zafi har sai kayan sun haɗa da sinadarai tare, ƙirƙirar sassa waɗanda suka fi ƙarfi fiye da simintin gyare-gyare na gargajiya ko na'ura.

Saboda iyawar sa, foda karafa ya zama sananne don samar da hadaddun sassa da ake amfani da su a cikin motoci, sararin samaniya da aikace-aikacen lantarki.

Mene ne babban zafin jiki mold?

Gyaran zafin jiki nau'in tsari ne na gyaran allura wanda ke amfani da yanayin zafi da matsa lamba don samar da sassa masu ƙarfi da karko.Tsarin yana aiki ne ta hanyar dumama ɗanyen kayan zafi na thermoplastic har sai ya narke sannan a yi masa allura a cikin wani nau'in da aka rufe inda aka ajiye shi a ƙarƙashin matsin lamba.Zafi daga narkakken guduro haɗe tare da matsa lamba yana haifar da abu zuwa siffar da ake so kafin sanyaya.Wannan tsari yana ba da damar ƙirƙirar sassa masu sarƙaƙƙiya waɗanda ke jure matsanancin yanayin zafi da sinadarai masu lalata, wanda ya sa su dace don amfani da su a cikin masana'antu kamar kera motoci, sararin samaniya, na'urorin likitanci da na lantarki.

Abubuwan Filastik na gama gari sun haɗa da: PEEK, PPSU, ULTEM® (Polyetherimide, PEI), Celazole®, Vespel®, Torlon® (Polyamide-imide) da sauransu.

Ƙirar ƙira don ƙirar zafin jiki mai girma

Lokacin zayyana gyare-gyare don robobi masu zafin jiki yana da mahimmanci a haɗa tashoshi na canja wurin zafi da kuma amfani da fitilun zafi don tabbatar da cewa filastik yana yin sanyi daidai lokacin aikin gyaran allura.

Bugu da ƙari, zaɓar kayan ƙirƙira daidai yana da mahimmanci don ƙirƙirar sassan da za su iya jure matsanancin zafi ba tare da faɗuwa ko tsagewa ba.

A cikin wannan aikin, mun yi amfani da karfe na S136 tare da HRC 52 ~ 54, samar da girma yana da girma sosai, ana buƙatar sassan 100000pcs kowace rana, don haka muka yi amfani da 8 cavity mold da kuma yin da yawa kwafi wadanda saduwa da yawa bukatar.Don sanyaya, an sanyaya shi da man fetur kuma zafin jiki ya kai digiri 120.Lokacin sake zagayowar shine daƙiƙa 9 kuma mun yi amfani da fitar da matakai 2 don sakin sassa.Za a kula da wannan ɓangaren zafi bayan gyare-gyare.

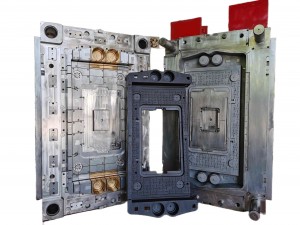

The allura mold kayan aiki ne 8 rami high zafin jiki allura mold.

Filastik kayan ƙarfe ne na foda kuma sassan da aka ƙera za su buƙaci maganin zafi kamar yadda mai haɗin wayar hannu.

Lokacin sake zagayowar allura ɗan gajeren lokaci ne, daƙiƙa 9 don harbi ɗaya.

Mun yi kayan aikin kwafi da yawa don wannan abokin ciniki.Masu zanen mu suna aiki da tasiri sosai, don DFM, an gama shi a cikin kwana 1, shimfidar 2D a cikin kwanaki 2, da 3D a cikin kwanaki 3.

Lokacin jagorar masana'anta shine makonni 4.

Don ƙirar ƙira, lokacin da lokaci yake da gaggawa, yawanci muna yin zane na 3D kai tsaye bayan DFM, amma ba shakka, dole ne ya dogara da amincewar abokan ciniki.

Tsarin 2D

3D mold zane

3D mold zane

FAQ

Babban kasuwancinmu shine yin gyare-gyaren filastik, yin gyare-gyaren simintin gyare-gyare, yin gyare-gyaren filastik, gyare-gyaren filastik, mutun simintin (Aluminum), mashin ɗin daidaici da saurin samfur.Har ila yau, muna samar da samfurori masu ƙima da suka haɗa da sassan silicon, sassa na karfe, sassan extrusion da bakin karfe

A'a, mu ne ainihin mold masana'antu da filastik allura gyare-gyare factory.Za mu iya samar da hoton rajista don tunani da duk wani bayanin da kuke so idan an buƙata.A halin yanzu, zaku iya ziyartar mu kowane lokaci, koda ba alƙawura ba.

Ƙungiyar lokacin rana tana ba da salon aikin sabis na 24/7.Don hutun jama'ar kasar Sin, tallace-tallacenmu da injiniyoyinmu na iya ɗaukar aikin kari ga kowane gaggawar ku.Kuma idan akwai larura, za mu yi iya ƙoƙarinmu don neman ma’aikata su ɗauki aikin kari a lokacin hutu ta hanyar canjin rana da dare don biyan bukatunku na gaggawa.

Muna da fiye da shekaru goma fitarwa gwaninta zuwa kasuwannin duniya, fitarwa filastik allura mold, mutu jefa mold, mutu simintin sassa, roba gyare-gyaren kayayyakin da CNC machining aka gyara da dai sauransu,.

Domin mold masana'antu, muna da CNC, EDM, nika inji, milling inji, hakowa inji, da dai sauransu,.Don gyare-gyaren filastik na al'ada, muna da injunan allura 4 daga ton 90 zuwa tan 400.Don ingantacciyar dubawa, muna da hexagon CMM, Projector, mai gwada taurin ƙarfi, ma'aunin tsayi, caliper vernier da sauransu.