5 Nau'in alluran allura bisa ma'aunin US SP1-SPE

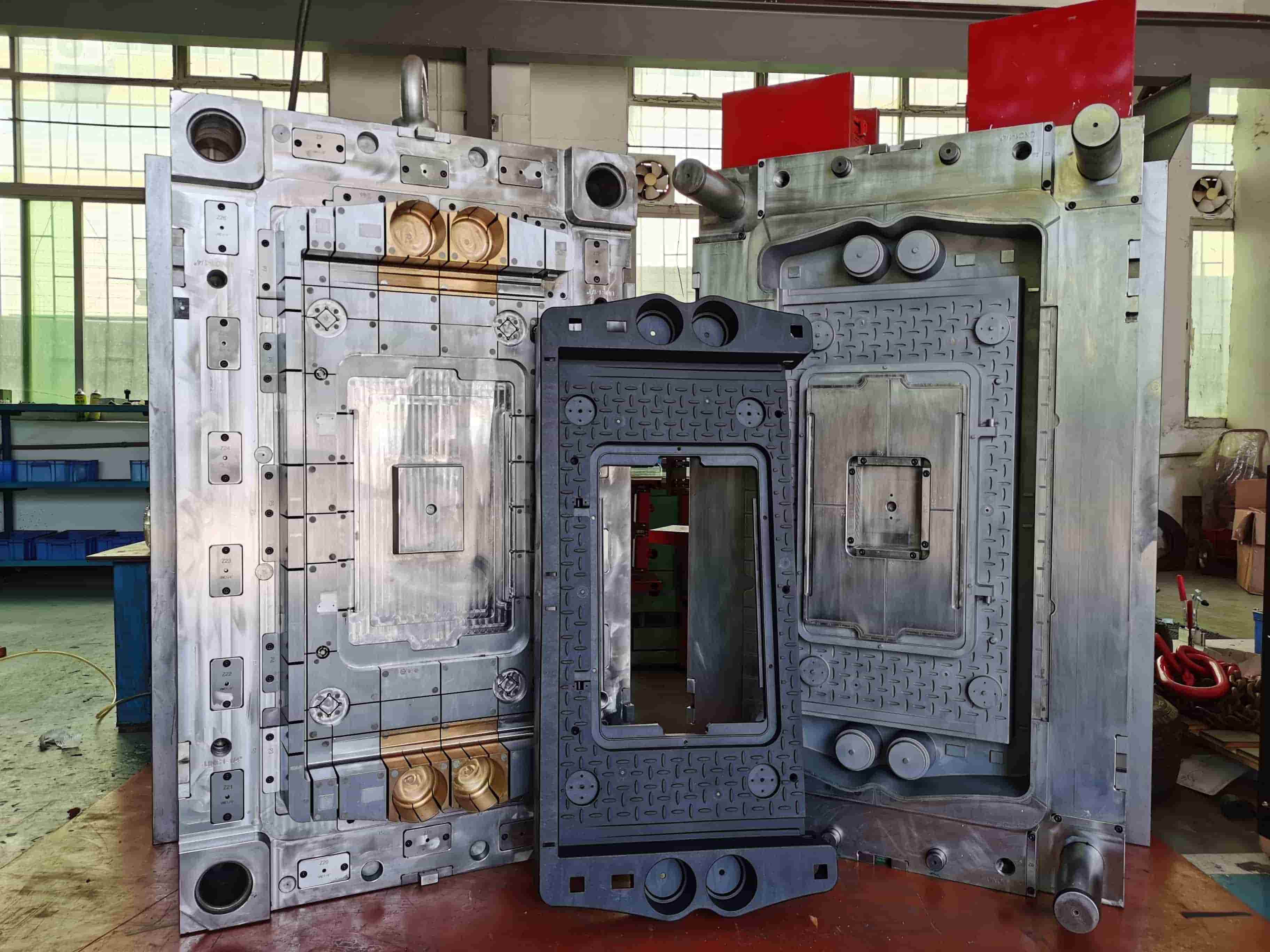

Idan kuna buƙatar haɓaka samfuri ko aiki, kayan aikin kayan masarufi abin ɗaukar kaya ne da babu makawa, kuma kwandon filastik a halin yanzu ya shahara sosai.Samar da harsashi na filastik dole ne ya kasance ba zai iya rabuwa da nau'ikan allura ba.Kamar yadda wani Sin allura mold manufacturer da maroki, muna da fiye da shekaru 10 na fitarwa kwarewa da kuma saba da mold bukatun na abokan ciniki a kasashe daban-daban.Yau za mu yi magana game da abin da nau'in mold na US SP1-SPE misali suke, kuma ina fata zai kasance da amfani a gare ku.

1. Class 101 molds (SP1-SPE misali 1,000,000 giya ko fiye, dogon lokacin da daidaici samar molds)

1).Ana buƙatar cikakken zane-zanen tsarin ƙirar ƙira;

2).M taurin mold blank abu ne 28HB (DME #2 karfe / sarki abu electroplating nickel / P20 electroplating Nickel);

3).Karfe na ciki module tare da manne dole ne a taurare zuwa 48 ~ 52HRC, da kuma sauran sassa kamar jere matsayi, latsa makullin, beading, da dai sauransu ya kamata kuma hardware;

4).Dole ne farantin mai fitarwa ya kasance yana da ginshiƙan jagora;

5).Layuka

6).Idan ya cancanta, ƙirar babba, ƙananan ƙira da matsayi na jere dole ne su sami ikon sarrafa zafin jiki;

7).Ga duk tashoshi na ruwa, ana bada shawarar yin amfani da dipping nickel mara amfani ko 420 bakin karfe a matsayin samfuri, wanda zai iya hana tsatsa da tsaftace datti;

8).Ana buƙatar madaidaicin kulle ko kulle-kulle.

2. Type 102 kyawon tsayuwa (ba fiye da 1,000,000 giya, taro samar da molds)

1).Ana buƙatar cikakken zanen tsarin ƙirar ƙira;

2).Matsakaicin taurin kayan tushe shine 165BHN (DME #2 karfe / AISI1050);

3).Na'urorin ciki tare da manne matsayi Dole ne a taurare karfe zuwa mafi ƙarancin 48 ~ 52HRC, kuma sauran sassa masu amfani ya kamata a bi da su kamar haka;

4).Ana ba da shawarar yin amfani da makullin madaidaici ko maƙallan maɗaukaki;

5).Ana iya buƙatar abubuwa masu zuwa ko a'a, ya danganta da adadin samarwa na ƙarshe.Ana ba da shawarar a faɗi Lokacin amfani da abubuwa masu zuwa, duba ko ya zama dole: A. Ejector farantin jagorar post, B. Matsayi mai wuyar layi, C. Electroplating rami isar ruwa, D. Electroplating mold cavity.

3. Type 103 molds (kasa da 500,000 giya, matsakaici-girma samar molds)

1).Ana buƙatar cikakken zane-zanen ƙirar ƙira;

2).Matsakaicin taurin kayan tushe shine 165BHN (DME # 1 karfe / 1040 karfe / S50C);

3).The karfe abu na ciki mold ne P20 (28 ~ 32HRC) ko high taurin (36 ~ 38HRC);

4).Sauran abubuwan da ake buƙata sun dogara da bukatun.

4. Type 104 molds (kasa da 100,000 giya, kananan samar molds)

1).Ana buƙatar cikakken zanen tsarin ƙirar ƙira;

2).M karfe ko aluminum (1040 karfe) za a iya amfani da mold tushe abu P20 (28 ~ 32HRC);

3).Za a iya amfani da gyare-gyaren ciki na Aluminum, karfe mai laushi ko wasu karafa da aka yarda;

4).Sauran buƙatun sun dogara da buƙatun.

5. Type 105 molds (kasa da 500 giya, na farko mold ko gwajin mold)

Ana iya amfani da simintin aluminum ko resin epoxy ko kowane abu muddin yana da isasshen ƙarfi don samar da mafi ƙarancin adadin gwaje-gwaje.

Lokacin aikawa: Jul-10-2023